Product Highlight

About Us

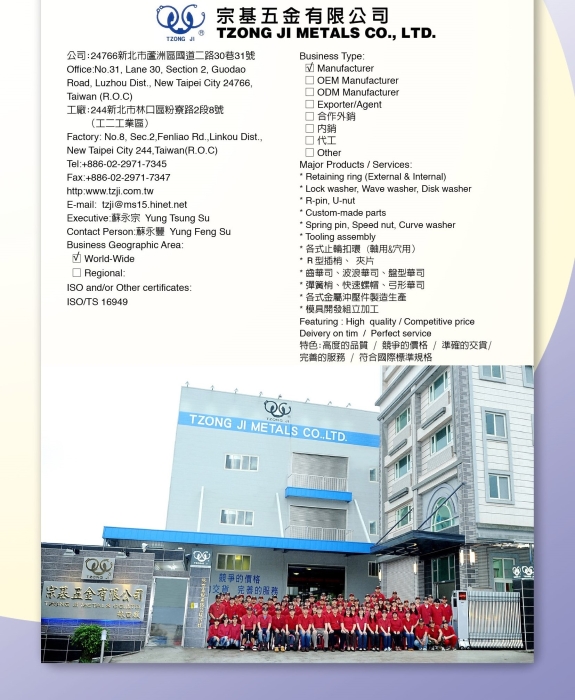

Since the establishment of Tzong Ji Metal Co. in 1988, in gratitude to all our customers for their cordial patronage and support we continuously grow up in both oversea and domestic industrial fasteners markets, and finally play a pivotal role in the field of retaining rings and clips. We fully applied our long accumulated experiences to tooling development. With the help of self-owned MITSUBISHI wire cutting machine, we adopt a thoroughly integrated process including tooling design, cutting steel plates, tooling assembly, and stamping manufacturing;and in view of promoting the production we modified the original tooling design for retaining rings to reduce the drawbacks in manufacturing process. National patents for new designs of molds for producing retaining rings and wave washers were also approved in the past years. After incessant struggles for achievement of high quality products and content service standards, we became the first company in this field to acquire ISO 9002 certification in Taiwan. Therefore, in order to further reduce cost and surpass our competitors, Tzong Ji Metals invested a new factory in 2009 in Taiwan and purchased a large number of production machines like special purpose machines and testing machines...etc., so as to expand production capacity to supply all customers and especially the valued long-term customers. In 2011, our new factory was completed and our production capacity was increased by 50%. In expectation of controlling the critical production process to meet the demands from our automobile manufacturing customers, in 2013 we purchased a salt bath heat treatment furnace (Austempering) and a X-ray instrument for coating thickness measurement. With these in-house equipments we can get better control of the quality and the yield. It is well known that austempered fasteners show excellent performance on strength and wear resistance. In the same year we also purchased several automation machines and sorting machines so as to expedite the delivery schedule. In 2013, for getting further trust from customers we started to implement ISO/TS 16949 quality management system and got the certificate in 2015. In 2016, after we purchased several automated optical inspection machines, our product quality is boosted to a higher level now.